Key Facilities & Units

2D & 3D Product Development

We have dedicated product development capabilities, utilizing advanced 2D and 3D design technologies to create innovative and customized metal components.

Raw Material Unit

Our well-equipped raw material unit ensures that we have a reliable supply of top-grade materials, such as brass, copper, iron, steel, and aluminium.

Forging Unit

The forging unit enables us to forge and shape metal components with precision and strength, meeting the specific requirements of our clients.

Polishing Deburring Machine

We utilize advanced polishing and deburring machines to achieve smooth finishes and remove any imperfections from the metal components.

Power Press

Our power press machines aid in various metalworking operations, including cutting, bending, and shaping.

Vertical Machining Centres (VMC)

Our VMC ensure precise and efficient machining, crafting intricate components with the utmost accuracy. From diverse materials to tight tolerances, our VMCs deliver flawless quality.

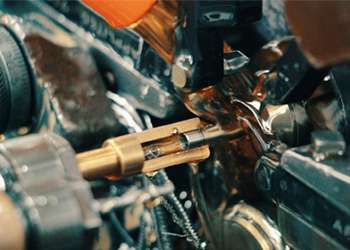

Computer Numerical Control (CNC)

Powered by cutting-edge CNC technology, our machines create components with unparalleled precision. Programmed instructions and meticulous craftsmanship guarantee.

HMC Horizontal Machining Center

Our HMC unit is equipped with cutting-edge technology and advanced features, enabling us to achieve unparalleled precision, efficiency, and productivity in our machining processes.

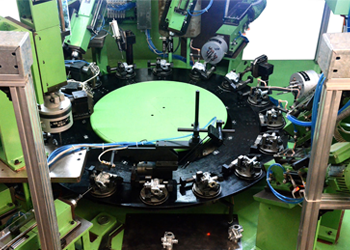

Automatic Machine Units

Our range of automatic machines allows for efficient and consistent manufacturing processes, increasing productivity and reducing lead times.

TMC (Toolroom Machine Center)

Our TMC is equipped with versatile machining capabilities, enabling us to handle complex and intricate metal components.

SPM (Special Purpose Machine)

Our SPMs are specifically designed and customized for unique manufacturing requirements, ensuring efficient and precise operations.

Multi-Tasking for Special Purpose

Our multi-tasking machine enables us to perform multiple operations on a single machine, enhancing productivity and reducing setup times.

Milling Machine Vertical

With our vertical milling machine, we can achieve accurate and precise milling operations on metal components.

SPM Slotting Machine

Our SPM slotting machine allows us to create precise slots and grooves on metal components, meeting specific design requirements.

Centerless Grinding Machine

We utilize centerless grinding machines to achieve high-quality grinding and finishing of cylindrical metal components.

Visual Inspection

Our dedicated visual inspection area ensures that each component undergoes thorough quality checks and meets our stringent standards.

Assembly Unit

Within our well-equipped assembly unit, components come together seamlessly, creating functional and precise products.

Packing Unit

Safety in transportation is paramount. Our dedicated packing unit ensures that each product is securely packaged, safeguarding it against any potential damage during transit.

Quality Control Laboratory

Our in-house quality control laboratory is equipped with the latest instruments and tools to conduct comprehensive quality checks and tests.

Tools Workshop

We maintain a dedicated tools workshop to support the maintenance and calibration of our machinery and equipment.

Admin Office and Conference

Our administrative office and conference facilities serve as the central hub for our administrative operations and meetings.

At Mukul Metals Pvt. Ltd., our robust infrastructure forms the backbone of our operations, allowing us to consistently deliver high-quality, customized metal components to meet the diverse needs of our clients.